Loading...

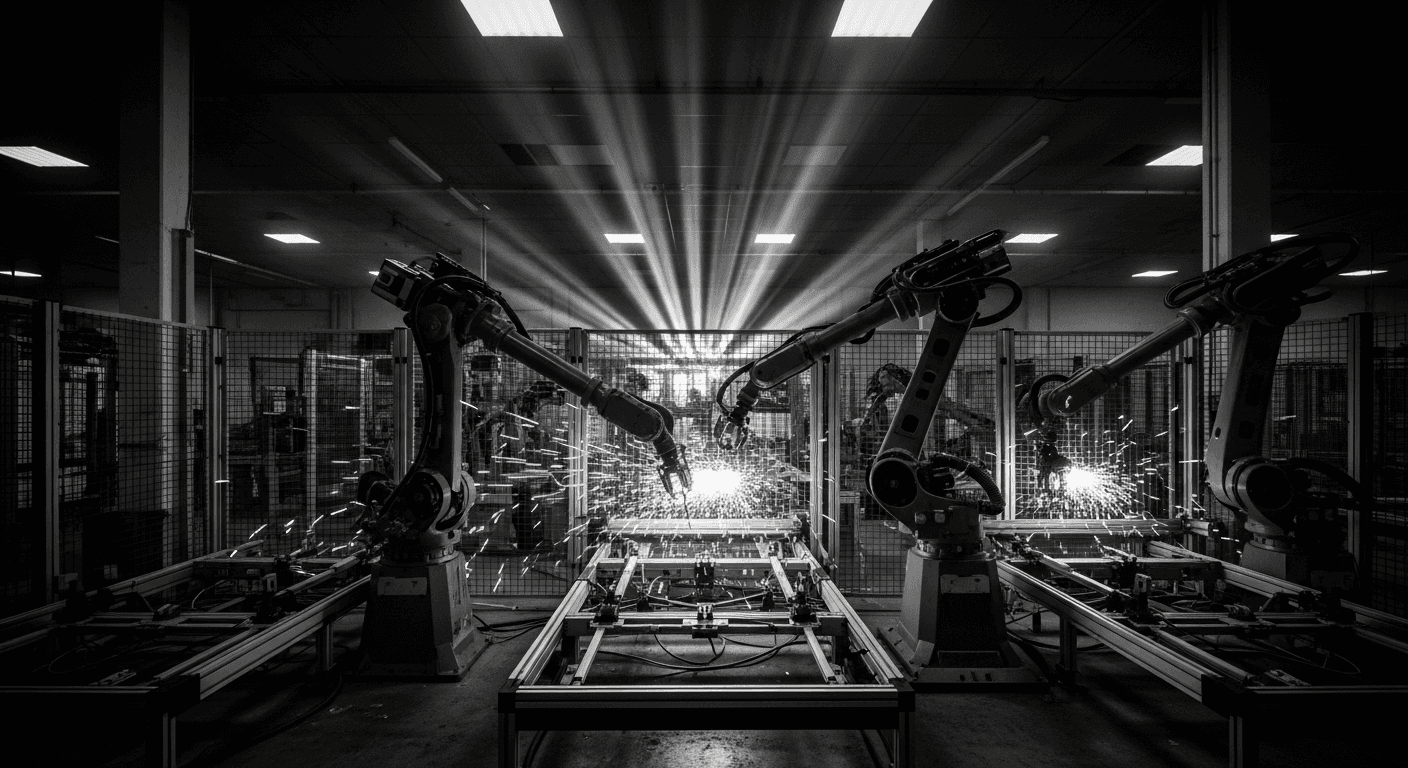

A production line goes down unexpectedly. The part that failed costs $200. The unplanned downtime costs $50,000 in lost production. The expedited repair adds another $10,000. Customer orders get delayed. Penalties kick in. The total cost of that $200 part failing: north of $75,000.

Now imagine knowing three weeks in advance that the part was going to fail.

That is what AI predictive maintenance does. And it is the clearest, most quantifiable ROI case for AI in any industry.

Predictive Maintenance Changes the Economics

Manufacturing has always had maintenance strategies. Reactive maintenance fixes things when they break. Preventive maintenance services equipment on a schedule, whether it needs it or not. Both are expensive in different ways. Reactive maintenance costs more in downtime. Preventive maintenance costs more in unnecessary service.

Predictive maintenance threads the needle. AI agents analyze vibration data, temperature readings, power consumption patterns, acoustic signatures, and dozens of other sensor inputs to predict when a component will fail. Not if. When.

The manufacturer schedules the repair during a planned downtime window. The part is ordered in advance at standard pricing, not expedited. The technician has the right tools and procedures ready. What was a $75,000 emergency becomes a $500 scheduled maintenance task.

Early adopters report 30-50% reduction in maintenance costs. That number alone justifies the investment. But the secondary effects matter too. Equipment runs longer because it is maintained when it needs maintenance, not before or after. Unplanned downtime drops by 50-70%. Production scheduling becomes more reliable because equipment availability is more predictable.

Quality Control at Machine Speed

Human quality inspectors are skilled and important. They are also inconsistent. Inspector fatigue is a real, documented phenomenon. The defect detection rate at 2 PM is measurably different from the defect detection rate at 2 AM. Humans get tired. Their attention drifts. They miss things.

Computer vision AI inspects every unit on the production line with identical attention. It does not have a bad day. It does not get distracted. It catches the hairline crack on unit 10,000 with the same probability as on unit 1.

The sophistication of manufacturing quality AI goes beyond simple pass/fail inspection. AI systems learn the difference between acceptable variation and genuine defects. A surface scratch that is cosmetically irrelevant gets classified differently from a surface scratch that indicates a structural issue. This nuance reduces false rejections, which is as important as catching real defects.

Real-time quality data also feeds back into process control. If the AI detects a trend toward a specific defect type, it alerts process engineers before the defect rate becomes a problem. Maybe a tool is wearing. Maybe a raw material batch has different properties. The early warning enables process adjustment before significant production is affected.

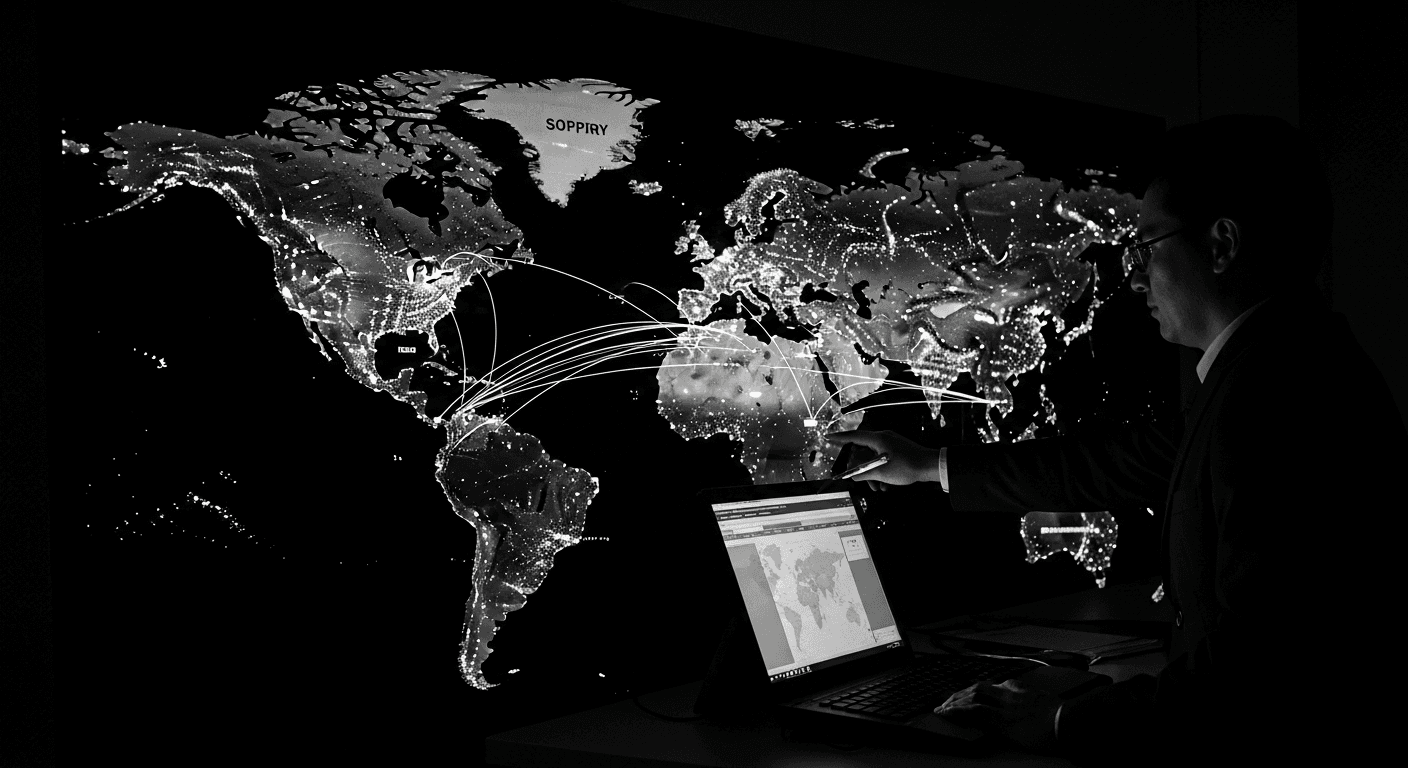

Supply Chain Intelligence

Manufacturing supply chains are global, complex, and fragile. A supplier delay in one country cascades through production schedules across continents. Traditional supply chain management relies on manual tracking, periodic check-ins, and reactive firefighting when problems emerge.

AI supply chain agents monitor supplier performance, logistics tracking, inventory levels, and external risk factors continuously. They identify potential disruptions before they impact production. A port congestion event in Asia triggers automatic evaluation of affected inbound shipments, identification of alternative suppliers, and adjustment of production schedules.

The demand forecasting component is equally valuable. AI agents analyze order patterns, market trends, seasonal factors, and leading indicators to predict demand with higher accuracy than traditional forecasting methods. Better demand forecasts mean more accurate production planning, which means less finished goods inventory and fewer stockouts.

One manufacturer told me their AI supply chain system identified a potential raw material shortage six weeks before it would have impacted production. They secured supply from an alternative source at standard pricing. Their competitors, who reacted when the shortage actually hit, paid 3x premium pricing for emergency supply. The AI system paid for itself with that single incident.

Production Planning and Optimization

Scheduling a manufacturing operation is a problem of staggering complexity. You have multiple machines with different capabilities. Multiple products with different processing requirements. Multiple orders with different priorities and deadlines. Material constraints. Labor constraints. Setup time between product changeovers. Quality requirements that vary by customer.

Humans solve this problem through experience and heuristics. They produce schedules that work, but they do not produce optimal schedules. They cannot. The number of possible schedule permutations exceeds what the human brain can evaluate.

AI production planners evaluate millions of schedule possibilities and select the one that maximizes throughput while meeting all constraints. They factor in variables that human planners consider sequentially. Machine A needs maintenance Thursday, so products requiring Machine A should be scheduled before Thursday, but Product X has a Friday deadline and requires Machine A and Machine B in sequence, and Machine B has a setup changeover...

The AI considers all of this simultaneously. The resulting schedules typically improve throughput by 10-20% compared to manual planning. For a factory producing $50M annually, a 15% throughput improvement is $7.5M in additional capacity from existing equipment.

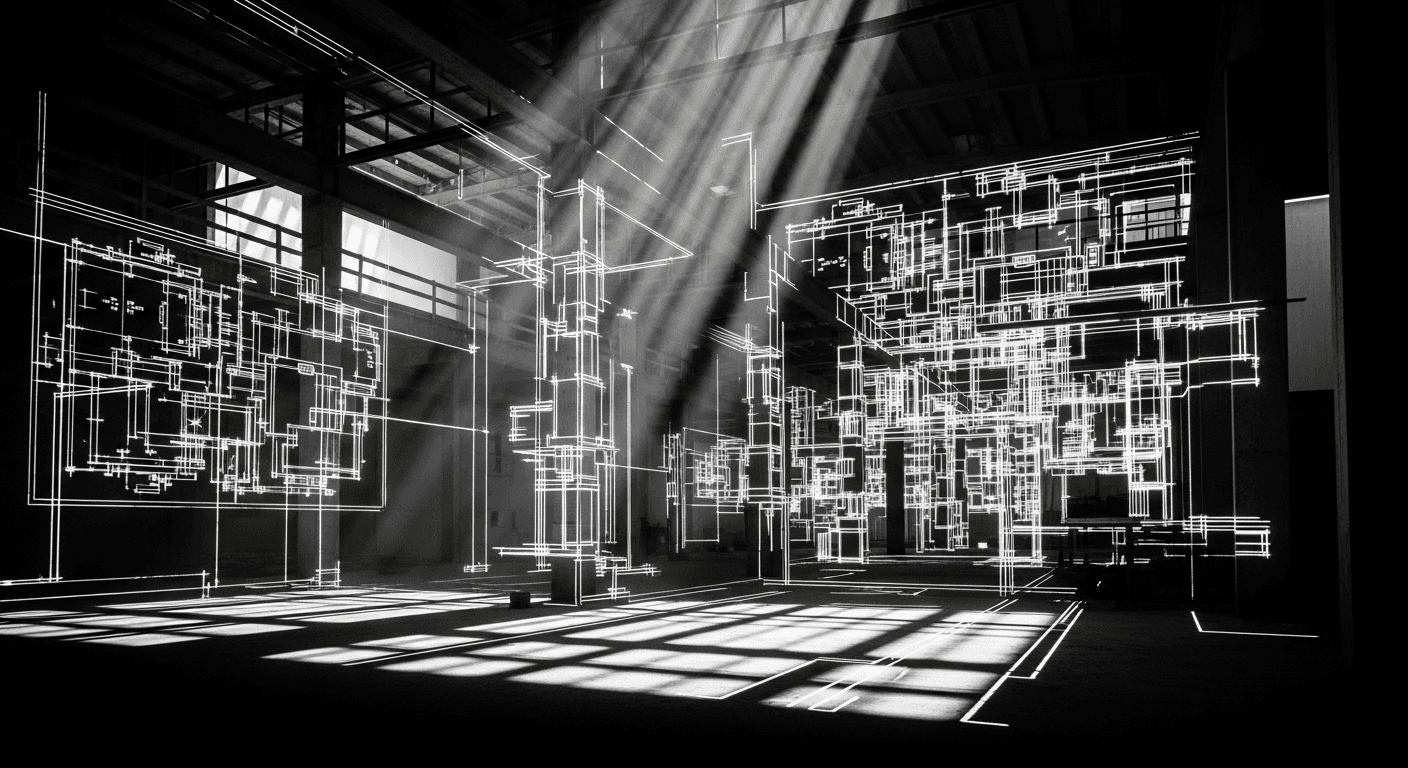

Digital Twins and Simulation

Advanced manufacturing AI creates digital twins of production processes. A digital twin is a virtual model that simulates the physical production environment. You can test process changes, evaluate new product introductions, and optimize parameters in the simulation before making changes on the actual production floor.

This eliminates the expensive trial-and-error of process optimization. Instead of running test batches and adjusting parameters based on results, engineers simulate hundreds of parameter combinations and identify the optimal settings before a single physical unit is produced.

The Implementation Reality

Manufacturing AI is not plug-and-play. The sensor infrastructure needs to be in place. Data needs to be clean and accessible. Integration with existing manufacturing execution systems and ERP systems needs to work. The technical prerequisites are significant.

But the return on investment is among the highest of any industry. Manufacturing deals in physical products, physical equipment, and physical time. The cost of downtime, defects, and suboptimal scheduling is measurable and large. AI improvements hit the bottom line directly and visibly.

The factories that start with predictive maintenance on their most expensive equipment and expand from there are the ones that build genuine competitive advantages. Not through technology for technology's sake. Through measurable improvements in cost, quality, and throughput that compound over time.

Related Articles

AI in Logistics: Optimizing the Supply Chain End to End

Logistics companies use AI for route optimization, demand forecasting, warehouse management, and real-time supply chain visibility.

AI in Construction: Smarter Project Management and Safety

Construction companies use AI for project scheduling, cost estimation, safety monitoring, and quality inspection at every phase.

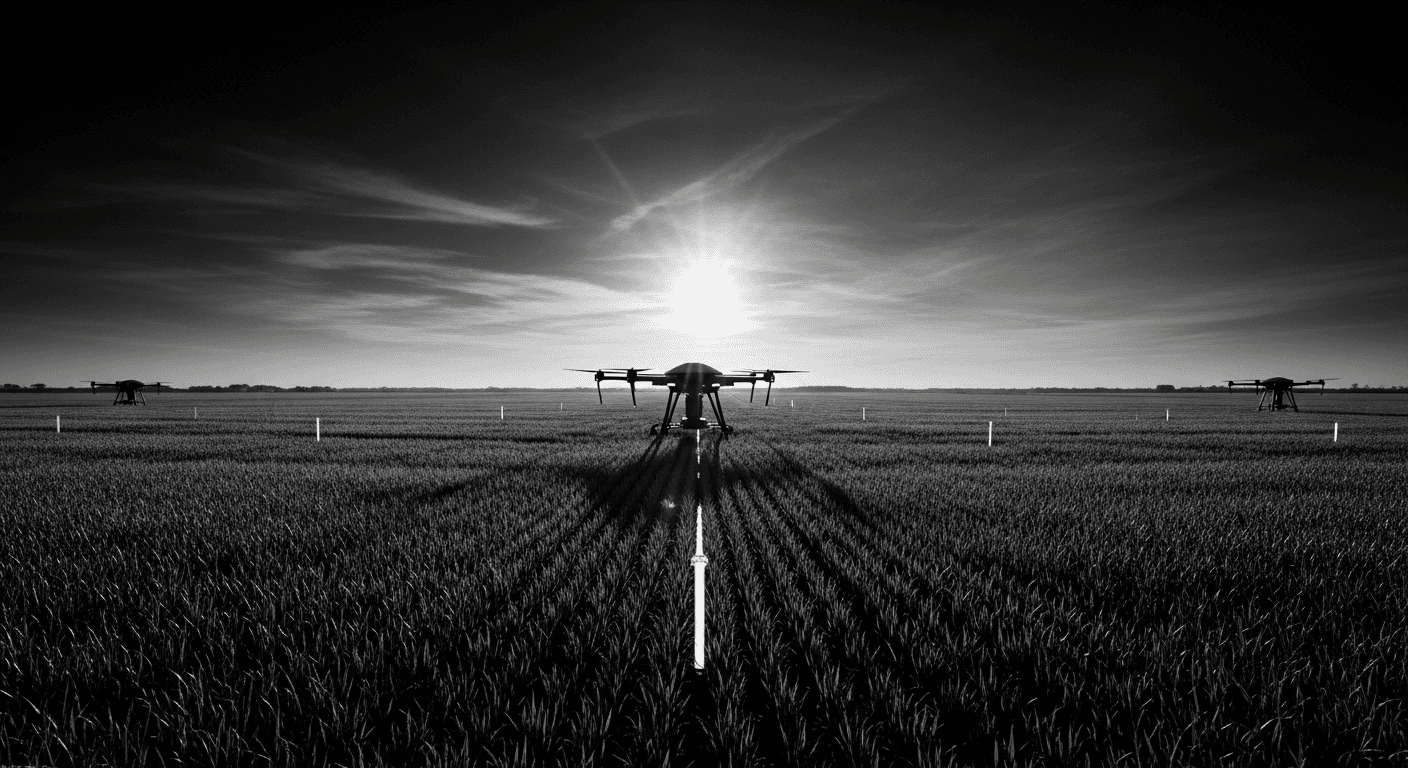

AI in Agriculture: Precision Farming and Crop Intelligence

Agricultural operations use AI for crop monitoring, yield prediction, resource optimization, and sustainable farming practices.

Want to Implement This?

Stop reading about AI and start building with it. Book a free discovery call and see how AI agents can accelerate your business.