Loading...

Farming is the original optimization problem. Too much water drowns the crop. Too little kills it. Too much fertilizer pollutes the groundwater. Too little starves the plant. The difference between a profitable season and a devastating one can come down to decisions made on incomplete information.

For ten thousand years, farmers relied on experience, intuition, and luck. AI adds precision to an equation that desperately needs it.

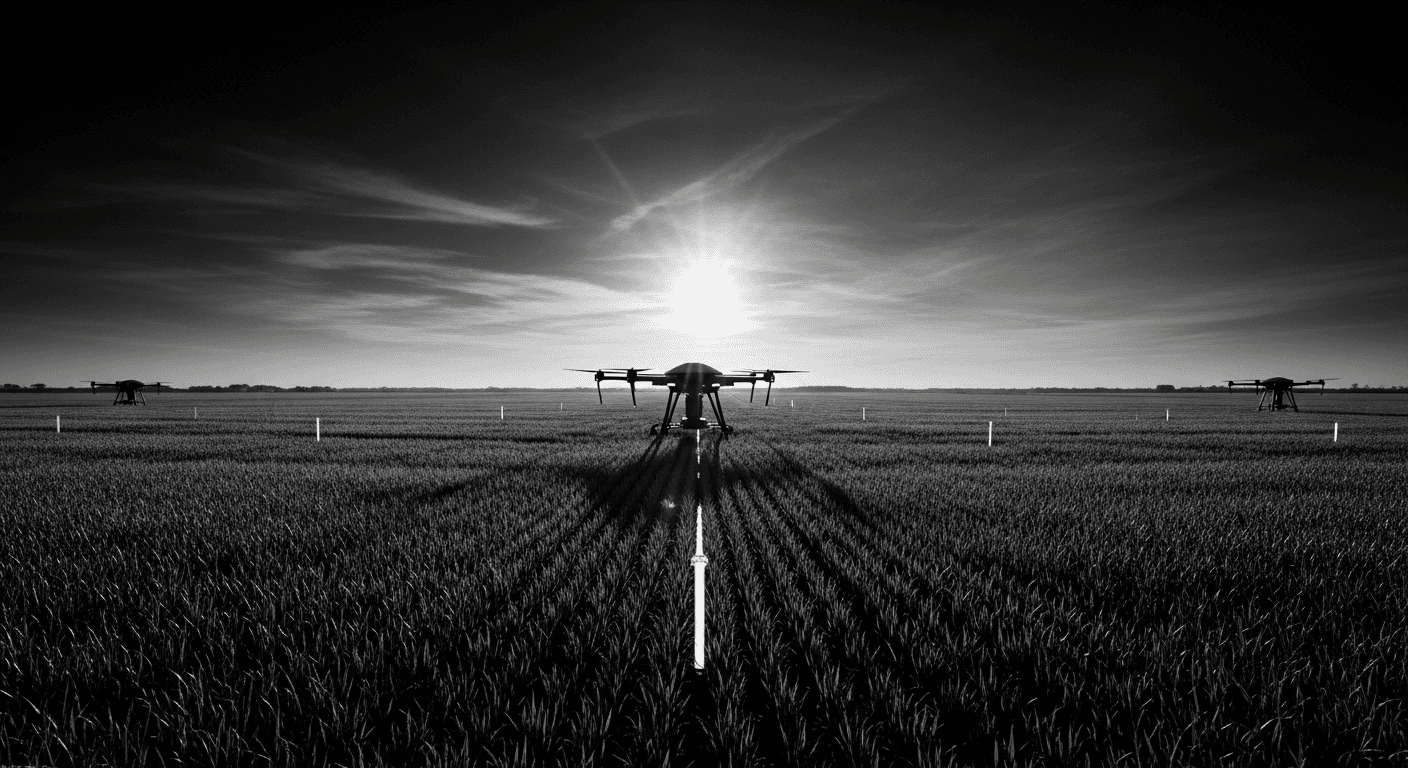

Seeing Every Plant from Space

A farmer walking their fields can inspect maybe 2% of their crop in a day. They check the rows they can reach. They look for obvious problems. They extrapolate from what they see to what they can't. "This section looks good, so the rest probably does too."

Satellite imagery plus AI crop monitoring flips this to 100% coverage. Every day.

Multispectral satellite imagery captures data across wavelengths the human eye can't see. Healthy plants reflect near-infrared light differently than stressed plants. Nitrogen-deficient crops have a distinct spectral signature. Water stress shows up days before visible wilting.

AI models trained on millions of acres of crop imagery read these signatures and translate them into actionable intelligence. "Section 4B shows early signs of nitrogen deficiency. Section 7A has a moisture gradient suggesting irrigation system inconsistency. The southwest corner of Field 12 has a disease pattern consistent with early blight."

Drone surveys add resolution where satellite data isn't detailed enough. A drone flying at 100 feet captures individual plant-level data. Enough detail to count plants, assess canopy cover, and identify weed pressure at a level that enables targeted response instead of blanket treatment.

The farmer goes from gut-feel management of a thousand acres to data-driven management of every individual section. Problems get caught early. Interventions get targeted precisely. Nothing gets missed because nobody walked that row this week.

Predicting the Harvest Before It Happens

Yield prediction used to be an art. Experienced farmers could look at their fields in July and make a reasonable guess about September's harvest. But "reasonable guess" doesn't help when you're negotiating forward contracts, planning storage capacity, or managing cash flow.

AI yield prediction models combine multiple data streams into forecasts that get more accurate as the season progresses.

Historical yield data establishes baselines. What did this field produce in similar conditions over the last 10-20 years? That's the starting point, but just the starting point.

Current season data refines the forecast. Actual rainfall versus historical averages. Growing degree days accumulated so far. Current crop health from imagery. Soil moisture levels from sensors.

Weather forecasts project conditions through harvest. Not just temperature and precipitation. Frost probability during critical growth stages. Hail risk. Extended heat stress periods that affect grain fill.

The result is a yield forecast that updates weekly with increasing confidence. Early season estimates might have a 20% confidence interval. By mid-season, that narrows to 10%. Six weeks before harvest, it's within 5%.

That precision enables better business decisions across the agricultural value chain. Farmers negotiate stronger contracts because they know what they'll deliver. Grain elevators plan storage allocation. Food processors schedule production runs. Everyone operates with better information.

Precision Application of Everything

The economics of farming are straightforward. Inputs cost money. Outputs make money. The gap between them is profit. Every dollar of unnecessary input erodes that margin directly.

Traditional farming applies inputs uniformly. The entire field gets the same fertilizer rate. The same herbicide application. The same irrigation schedule. But fields aren't uniform. Soil types vary. Topography affects drainage. Previous crop history differs by section. Weed pressure is heavier in some areas than others.

AI-driven precision application matches inputs to actual field conditions at a granular level.

Variable rate fertilizer application adjusts the rate every few meters based on soil nutrient maps, yield potential, and current crop needs. Areas with naturally fertile soil get less. Areas with deficiencies get more. The total fertilizer usage drops 15-25% while yields stay the same or improve because the right amount goes to the right place.

Precision irrigation delivers water based on actual soil moisture data, not timers. Sensors throughout the field report moisture levels. The AI determines which zones need water, how much, and when. Over-irrigated areas dry out. Under-irrigated areas get more. Water usage drops and crop stress decreases.

Targeted pest and weed management replaces broadcast spraying with surgical application. Computer vision on spray rigs identifies weeds in real time and activates individual nozzles only where weeds are present. Herbicide usage drops 70-90%. The environmental impact shrinks dramatically. And the farmer saves money on chemicals they don't need to buy.

Sustainability as a Side Effect of Efficiency

Here's the part that matters beyond farm economics. Every optimization that reduces input waste also reduces environmental impact.

Less fertilizer runoff means cleaner waterways. Less herbicide application means less chemical exposure for farm workers and less contamination of surrounding ecosystems. Less water waste means more water available for other uses in regions facing scarcity.

Precision farming with AI doesn't require farmers to choose between profitability and sustainability. The practices that save money are the same practices that protect the environment. Apply less. Apply better. Waste nothing.

For an industry that feeds 8 billion people and will need to feed 10 billion by 2050, doing more with less isn't just good business. It's an obligation. AI makes that obligation achievable.

Related Articles

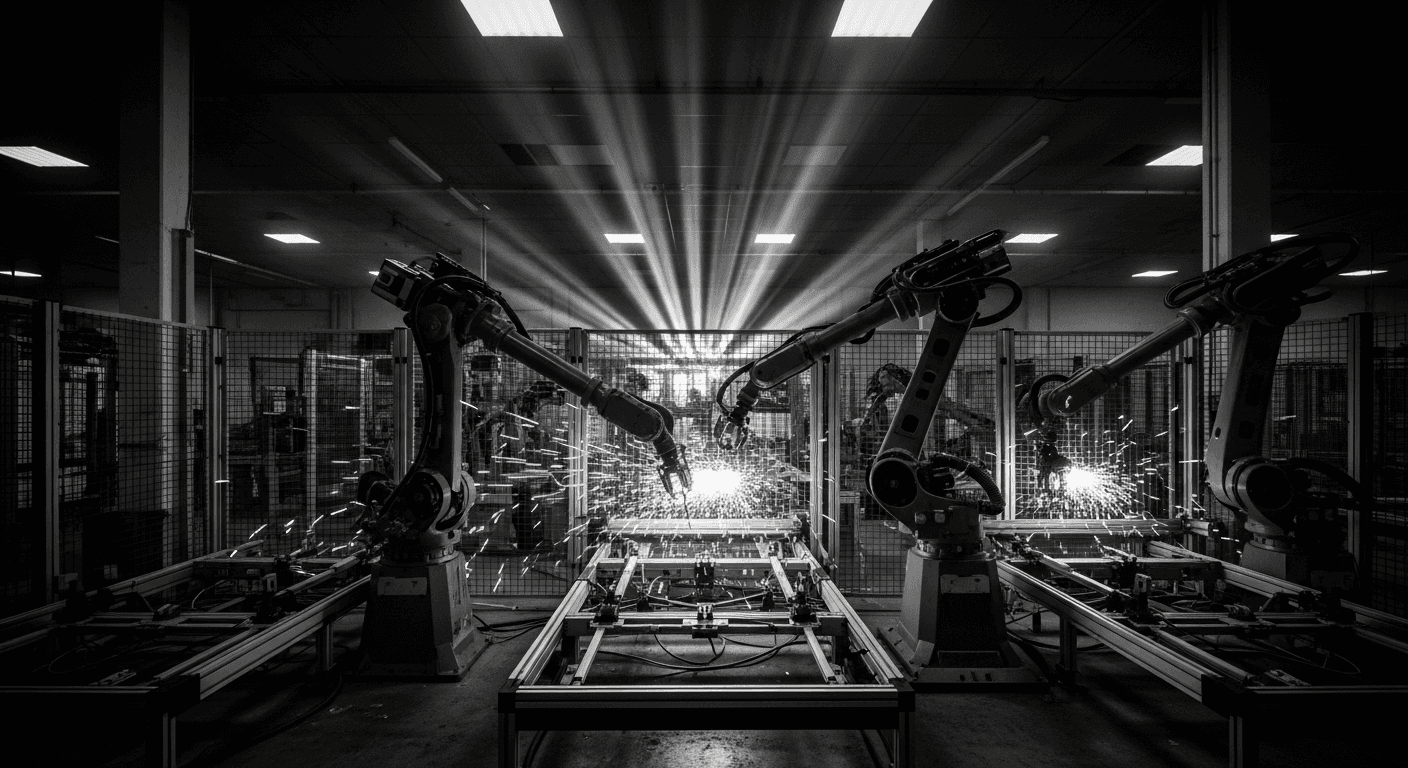

AI in Manufacturing: Building Smart Factories

Manufacturers deploy AI agents for predictive maintenance, quality control, supply chain optimization, and production planning.

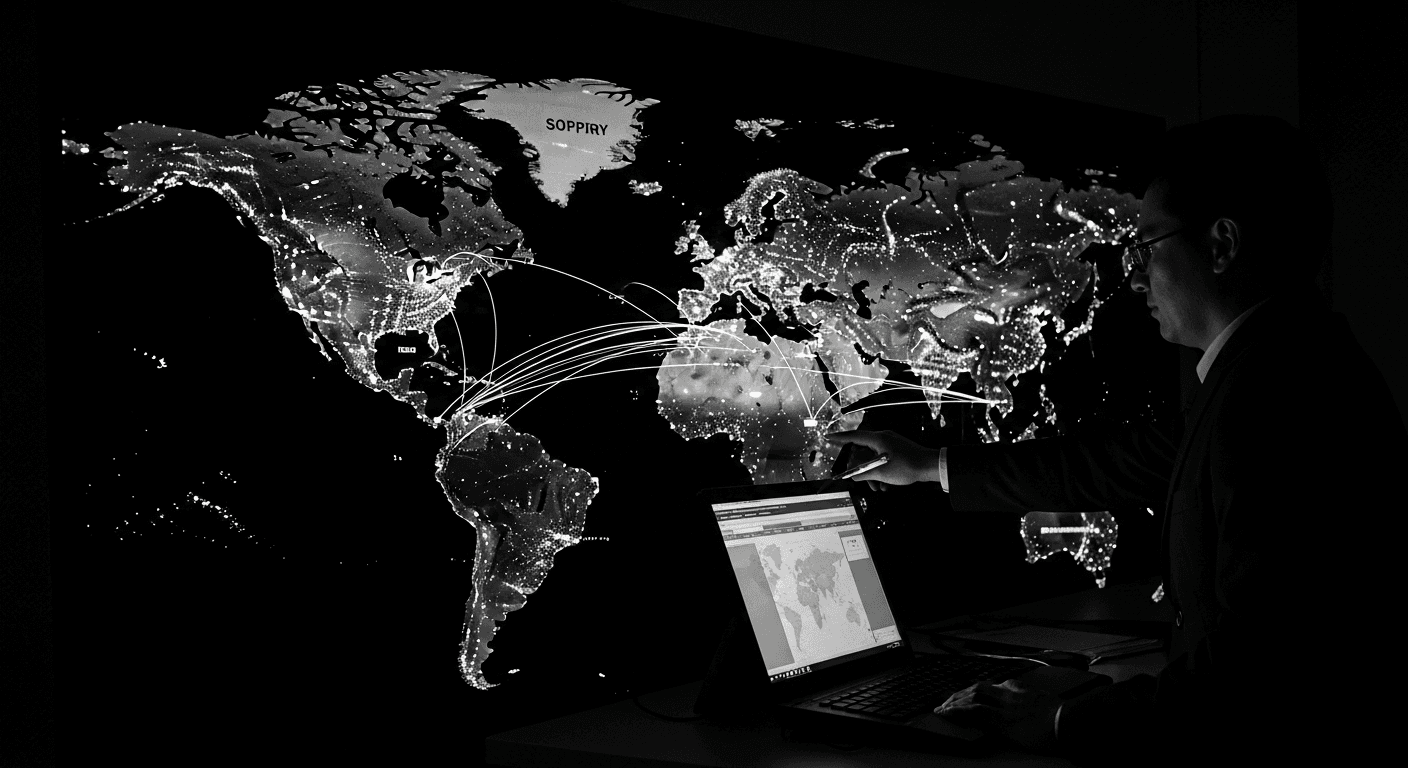

AI in Logistics: Optimizing the Supply Chain End to End

Logistics companies use AI for route optimization, demand forecasting, warehouse management, and real-time supply chain visibility.

AI in Construction: Smarter Project Management and Safety

Construction companies use AI for project scheduling, cost estimation, safety monitoring, and quality inspection at every phase.

Want to Implement This?

Stop reading about AI and start building with it. Book a free discovery call and see how AI agents can accelerate your business.